QUALITY CONTROL FLOW CHART

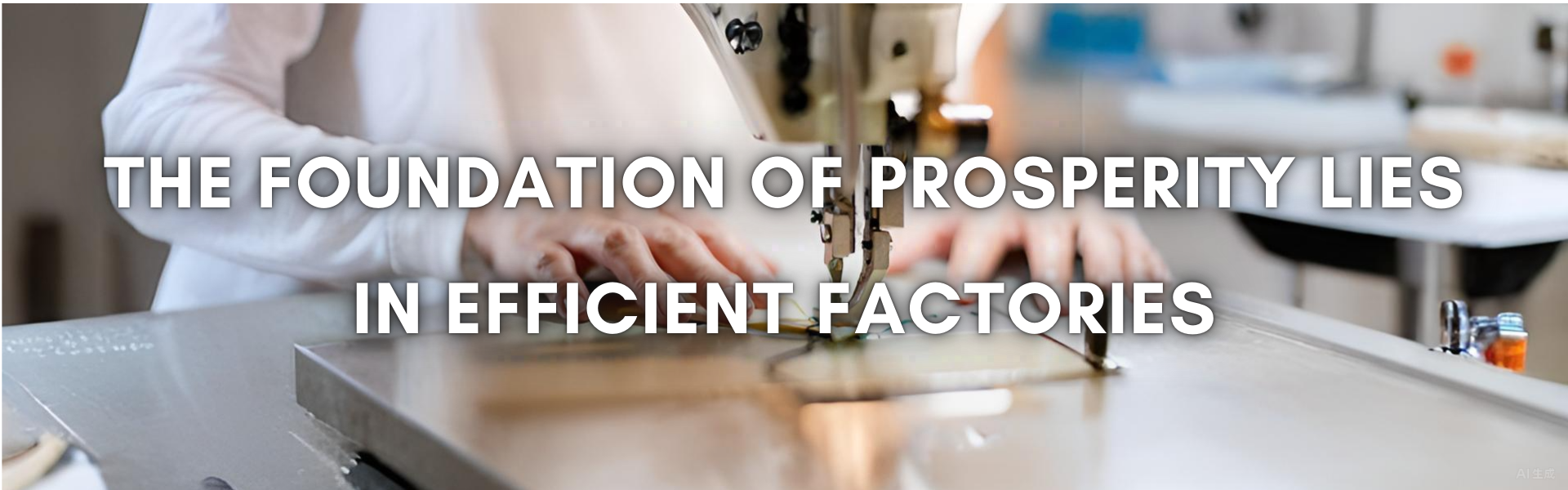

Our production facilities have triumphantly achieved compliance with rigorous certifications like BSCI and Sedex, as well as fulfilling the stringent requirements of esteemed clients, including the rigorous Zalando,NewYorker,CCC,LPP. Equipped with state-of-the-art facilities and expertise, we are fully capable of conducting a comprehensive range of chemical and physical tests, ensuring the utmost quality and safety of our products.

-

1.Implement process monitorin g and control measures to ens ure that each step is executea accordina to standards. This ca n be achieved through process flowcharts, checklists, and aut omated toos

Process Control -

1.Implement strict material ins pection procedures, includina checks on appearance, dimensi ons, performance, and other asoecis.

2.Conduct continuous monitori na and evaluation of critical m aterials to ensure they meet st andards and be prepared to re spond to potential changes at any time

Material Inspection -

1.Conduct inspections in the m iddle to late stages of the prod uction process to ensure that t ne product quanty meets the required standards

2.Implement process improve ment measures to reduce dete Cis and inconsistencies that ari se in the middle to late stages of production

Mid-to-late Stage Inspection -

1.Emphasize training to ensure employees understand and im plement quality standards

2.Conduct on-site inspections to ensure oper ations adhere to the standards

3.Establish a auality awareness training program to inspire em ployees' sense of responsibility for quality

On-site Management -

1.Regularly conduct quality tes ts to Identity existing issues an a propose improvement succeSTIOns.

2.Encourage employees to putforward improvement ideas ana establisn a Teedback mechan ism to ensure that issues can o e prompty resolvea

Continuous improvement -

1.Collect customer feedback an a Incorporate it into the qualit y management system to cont nuously improve products or s ervices

2.Establish a customer complai nt handling process to ensure tImely response and resolution of customer issues

Customer Feedback

English

English 中文

中文

TEL:

TEL: E-mail:

E-mail: Add:18 Fanggong Rd., Lucheng District Wenzhou City, Zhejiang Province,China

Add:18 Fanggong Rd., Lucheng District Wenzhou City, Zhejiang Province,China